Automotive LED Lighting: CSP and SM Chips

LED bulbs are here to stay and are someday supersede the halogen and eventually even the HID automotive headlights. At HIDCONCEPT.COM, LED bulbs are the hottest seller, and we are constantly increasing the line of DAMA LED products. Besides it's bright and crisp nature, it is energy efficient and has a longer lifespan. We get many inquiries about our LED products, but one question that the customers ask the most is, "What's the difference in between CSP and SMD?"

You may remember Danny Glover using the Motorola "Suitcase Phone" in the movie, "Lethal Weapon." Shit was big. "Lethal Weapon wasn't Mel Gibson's character, but the dang brick of a phone he was carrying around.

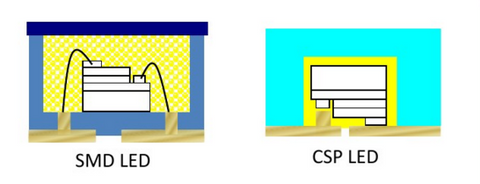

As we are all aware by now, the size of the phones has gotten smaller over time, and with all things tech-related, even LED also is going smaller and thinner. IN automotive LED lightings, SMD is a method where the chips are mounted on a holder and alloy wires are used to connect the chip to the PCB board. (See below) The downside of SMD is that 1) overload or surge of current can damage the alloy wire resulting in LED failure, 2) Due to the "extra" parts, it is considerably "thicker" than CSP LED.

CSP stands for "Chip Scale Package." Unlike SMD, CSP technology makes it possible for the chip to apply directly to the PCB board. By eliminating the need for a holder and alloy wire, this method bypasses two possible LED failure points. Also, CSP chips are smaller than SMD, but has a higher intensity and lower current consumption. DAMA MINI 194 with 9CSP (The number in front states the number of CSP chips) is a perfect example of how tiny LED signal lamp has so much light in a small package. In conclusion, CSP has the benefit that surpasses SMD and with anything tech-related, we feel that it may eventually be the more popular type of LED in the market.